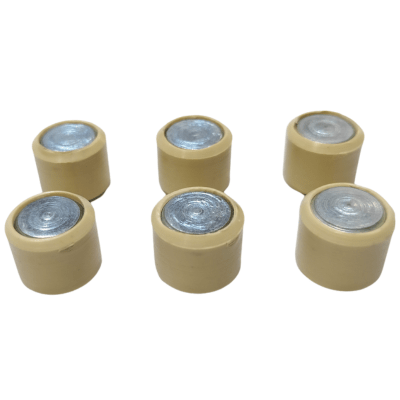

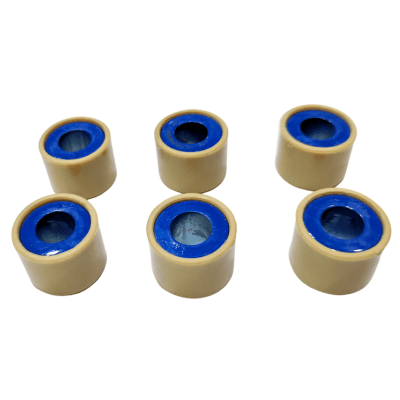

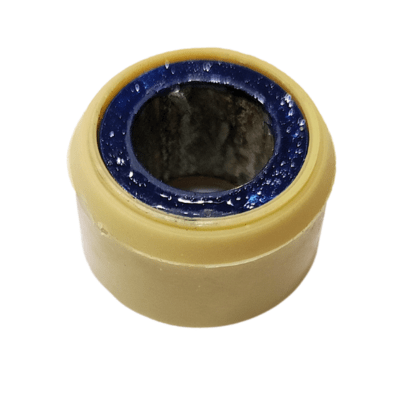

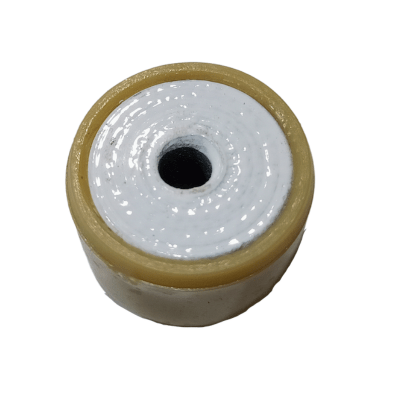

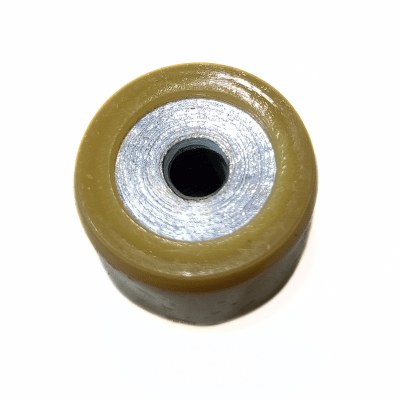

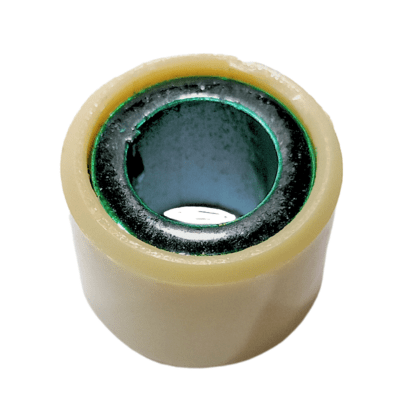

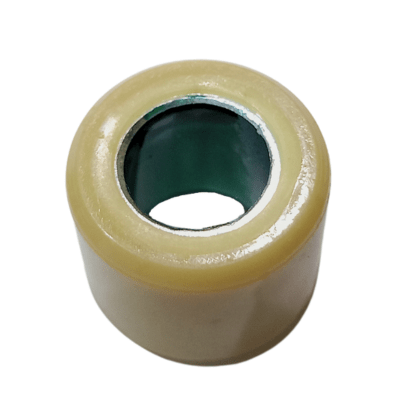

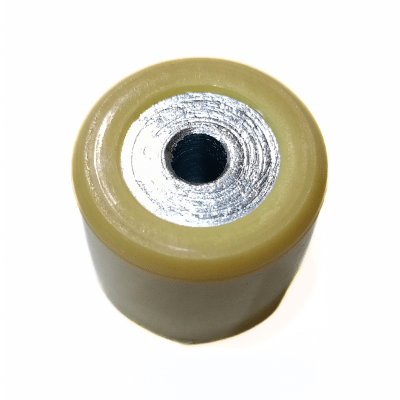

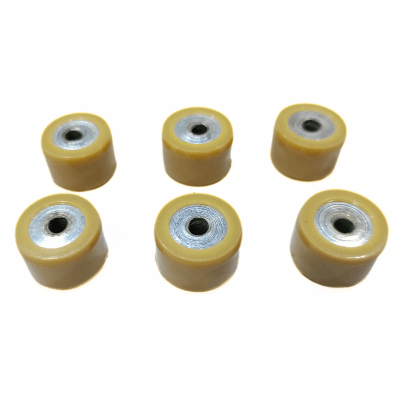

Roller Bush

Roller Bush, also known as Clutch Weights or Clutch Rollers Weights, are essential components of the clutch system in many two-wheelers, they play a crucial role in controlling the engagement and disengagement of the clutch, which, in turn, allows the rider to control the power transmission and speed of the vehicle.

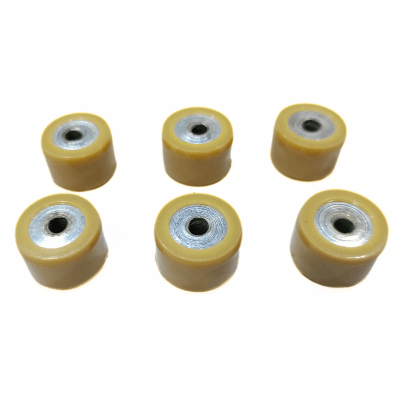

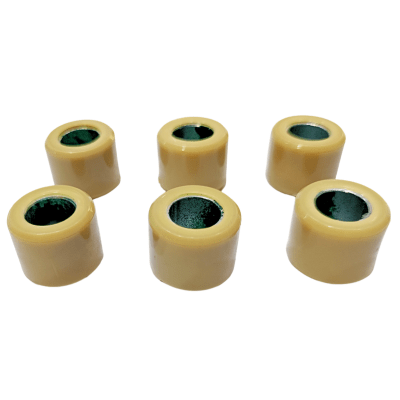

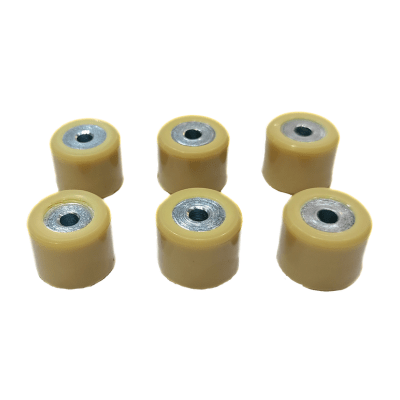

Clutch Rollers Variations Available

Yamaha Ray

Suzuki Access

Scooty Pep

Jupiter

Activa Old Model

Activa New Model

Activa HET

Wego

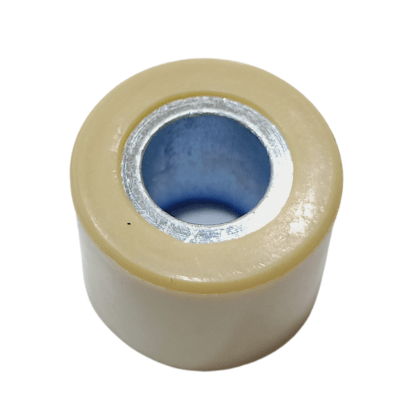

Shree Ambika Industries employs precision machining to craft clutch rollers.

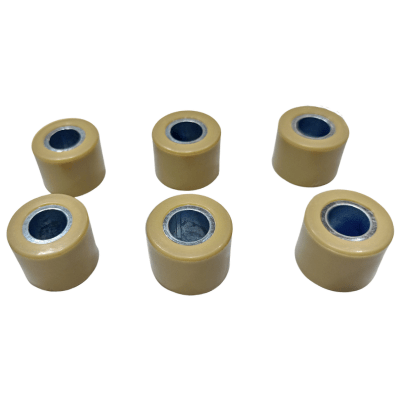

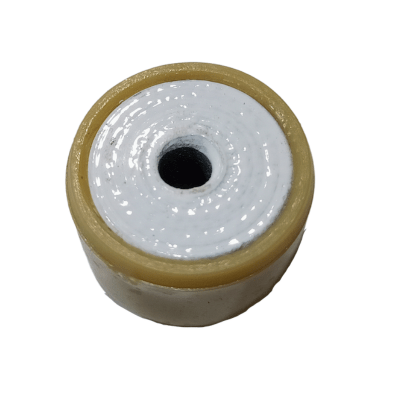

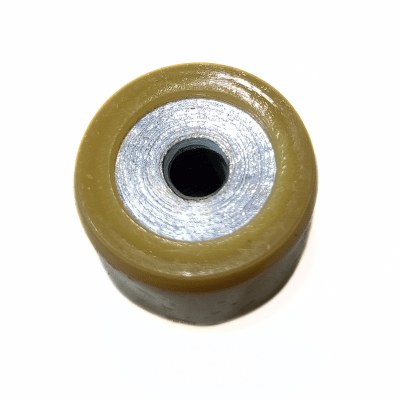

The preferred materials for clutch rollers typically include hardened steel, bronze, or other robust alloys capable of withstanding the abrasions caused by the clutch engagement and disengagement process. Manufacturers utilize precise machining consistently throughout the production process to ensure the rollers maintain uniform weights and dimensions. This step is crucial for preserving the correct operation of the clutch system. Manufacturers can also fine-tune roller weight to optimize clutch engagement and disengagement characteristics. Heavier rollers result in the clutch engaging at a higher RPM, while lighter rollers lead to a lower RPM engagement.

These components play a vital role in controlling the clutch’s engagement and disengagement, granting the rider command over the vehicle’s power transfer and speed.

The clutch rollers sit near the center of the clutch assembly while the engine operates at low or idle RPM. Consequently, the two-wheeler can remain stationary or move at a very slow pace with the clutch disengaged. Centrifugal force pushes the clutch rollers outward as the rider accelerates and the engine RPM increases. This action compels the clutch to engage, facilitating the transfer of power from the engine to the transmission and subsequently to the wheels. The engine RPM decreases when the rider applies the brakes or decelerates.

Explore All Products from Shree Ambika Industries

Applications Of Roller Bush

Suspension Systems:

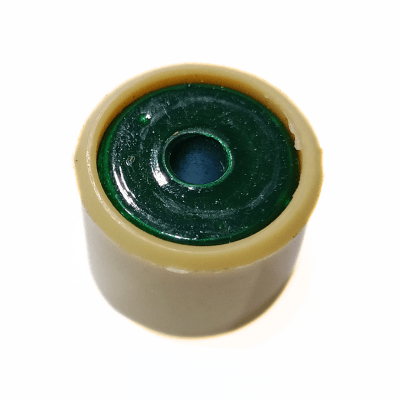

Suspension systems frequently utilize roller bushings at locations where components require pivoting or rotating. For example, in certain independent rear suspensions, you can locate roller bushings within the control arms or trailing arms. These components enable minimal friction movement, resulting in a smoother ride and enhanced handling.

Steering Systems:

Clutch rollers can be employed in steering systems to reduce friction and enhance steering precision. For example, they can be used in the steering column or intermediate shaft, allowing for smoother and more responsive steering.

Roller designs offer numerous advantages, including the ability to support both axial and radial loads, reduce friction, and enhance durability. Consequently, roller bushings prove ideal for applications requiring crucial load-bearing capability and rotational mobility.

In summary, clutch rollers employ needle bearings or rollers to reduce friction and facilitate smooth, controlled movement in various systems, such as suspension and steering. Their construction enhances the durability, handling, and ride quality of many essential automotive systems.

Contact Our Team To Get Information According to your Requirements or Book a Visit to Our Manufacturing Units!