Machines/Technologies:

- Rubber Moldings

- DG Set

- Hydraulic Machines

- Grinder

Main Manufacturing Unit

Welcome to our flagship rubber manufacturing facility. Our company, originally based in Delhi, relocated to Faridabad, marking the start of a new and improved chapter in our journey. Established in 2017, this unit has been the central hub of our operations since our relocation.

For over five years, this facility has been at the forefront of innovation and expertise in the production of high-quality rubber parts for two-wheelers. Starting from modest beginnings and growing into a multi-unit manufacturing company, this facility has been instrumental in shaping our corporate identity.

Throughout its history, our primary unit has pioneered numerous breakthroughs in rubber manufacturing. Our commitment to research and development has led to patented technologies that have redefined industry standards.

This facility has played a pivotal role in propelling our company’s growth, making substantial contributions to our market presence, reputation, and overall success. It remains the cornerstone of our operations as we continue to expand our horizons.

Book Your Visit Now!

New Manufacturing Unit:

Welcome to our state-of-the-art manufacturing facility, a symbol of progress and innovation that was recently established in 2021. This facility embodies our unwavering commitment to meeting the ever-evolving demands of the industry.

Our newly constructed unit is dedicated to the production of specialized rubber components designed for the most advanced two-wheelers available in the market. With a sharp focus on emerging trends, we provide components that seamlessly align with the latest technological advancements.

This facility is equipped with cutting-edge automation and robotics, enabling us to efficiently meet the growing market demands at scale. We are prepared to support the future growth of the two-wheeler industry.

In the brief time since its inception, our new unit has achieved remarkable milestones, from the rapid adoption of advanced production technologies to swift product development, setting new industry standards.

Machines/Technologies:

- Kneader Machines

- Extruder Machines

- Mixing Machines

- Ovens

Book Your Visit Now!

Pioneering Innovation For Superior Products

- CUTTING-EDGE TECHNOLOGY

At Shree Ambika Industries, our commitment to cutting-edge technology lies at the heart of our manufacturing process. We continuously strive to stay ahead of the competition by embracing the latest advancements in rubber part production. This dedication to innovation enables us to deliver products that not only meet but surpass industry standards in terms of performance, durability, and reliability.

- ADVANCED RESEARCH AND DEVELOPMENT

We invest significant resources in research and development to explore new materials, production techniques, and design concepts. Our team of engineers and researchers collaborate closely to identify emerging trends and technological breakthroughs that can revolutionize the rubber parts industry. This focus on R&D ensures that we remain at the forefront of innovation.

- STATE OF THE ART MACHINERY

We equip our manufacturing facilities with state-of-the-art machinery and equipment. These cutting-edge tools enable us to produce rubber parts with unparalleled precision and efficiency. The integration of advanced automation streamlines our production process, reducing the likelihood of errors and ensuring consistent quality across all our products.

- CONTINUOUS IMPROVEMENT AND ADAPTATION

Innovation is a continuous journey at Shree Ambika Industries. We consistently review our manufacturing processes and embrace improvements that can enhance the quality and performance of our products. As the technology landscape evolves, we adapt swiftly to integrate the latest breakthroughs into our operations, ensuring that our customers benefit from the best solutions available.

Machineries Used In The Factory

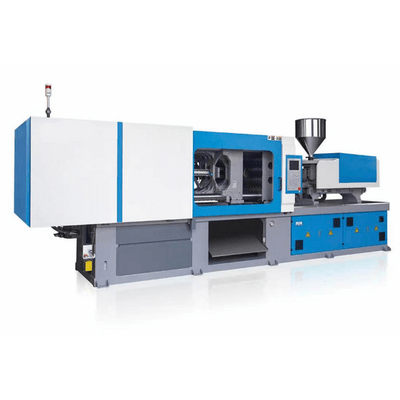

Injection Molding

Rubber Injection molding technology refers to various manufacturing processes that involve shaping rubber materials into specific forms and structures using molds or dies. These processes are used to produce a wide range of rubber products with consistent shapes, sizes, and properties.

Kneader Machine

Kneader machines are used for mixing and compounding rubber compounds. Those compounds are blends of rubber with various additives, fillers, and chemicals to gain specific properties such as strength, flexibility, and durability. The kneader machine helps in dispersing and blending these components evenly throughout the rubber matrix. Kneader machines are available in various sizes to meet the needs of different industries.

Compression Molding

We use Compression Molding machines for rubber manufacturing processes due to their ability to apply controlled and consistent force for various shaping, molding, and processing tasks. In rubber manufacturing, these machines play a crucial role in shaping and forming rubber into desired products.

Extruder Machine

Extruder Machine is used to process rubber compounds and create various rubber products. Extruder machines are available in different sizes and configurations, allowing manufacturers to tailor the equipment to their specific production needs. The versatility of extrusion technology makes it an essential tool enabling the efficient production of a wide range of rubber products with consistent quality and properties.

Grinders

Grinders are used to process rubber materials by reducing them into smaller particles. These ground rubber particles can then be used in various applications, such as in the production of new rubber products, as fillers, in coatings, and more. Grinding rubber also recycle waste rubber and create valuable materials for reuse.

Convection Oven

These ovens use fans to circulate hot air throughout the oven chamber, ensuring uniform heat distribution. In the case of petrol pipes, the rubber or plastic compounds are placed in the oven, and the convection heating helps to cure and harden the material evenly. Convection ovens offer precise temperature control and are suitable for batch processing or continuous production lines.

Make Shree Ambika Industries Your Source for All The Rubber Parts and Two-Wheelers Spare Part Needs

Get a FREE QUOTATION today or sign up to our news letter to learn more about our manufacturing and Rubber Products.