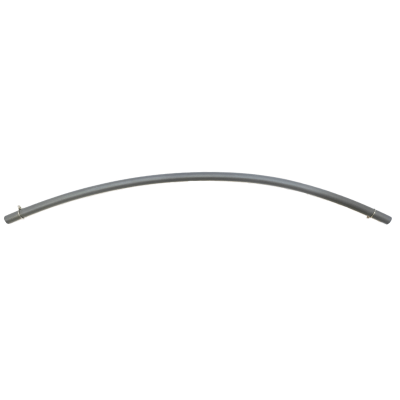

Petrol Pipes

Petrol Pipes in two-wheelers are critical components that transport fuel from the tank to the engine, allowing the vehicle to run efficiently. They are manufactured from materials designed to withstand the demands of the fuel system and are carefully designed to prevent leaks and ensure safety.

Variations Available

OVERFLOW PIPES

ACTIVA COTTON PIPE

BREATHER PIPE

Pulsar DTSI (6-Hole)

Super Splendor

Discover

Boxer/ CT-100

Pulsar DTSI (6-Hole)

Super Splendor

Discover

Boxer/ CT-100

Pulsar DTSI (6-Hole)

Super Splendor

Discover

Boxer/ CT-100

At Shree Ambika Industries, Petrol Pipes are manufactured by using a process called Extrusion.

Petrol Pipes are typically made from flexible, durable materials that can withstand exposure to gasoline and the mechanical stresses associated with a two-wheeler’s operation. Common materials include rubber, synthetic rubber compounds, or plastic polymers. The manufacturing process often begins with extrusion, where the chosen material is melted and forced through a die to create a continuous tube-like shape. This extrusion process ensures a consistent diameter and wall thickness for the pipe. These materials are chosen for their resistance to corrosion and flexibility. In some cases, especially for high-performance or heavy-duty applications, the petrol pipes may include layers of reinforcement, such as nylon or polyester fabric, to enhance strength and prevent kinking or collapsing. To protect the petrol pipe from external elements and minimize the risk of fuel leakage, it is often coated with a protective layer, which could be another layer of synthetic rubber or a specialized coating. After the petrol pipe is manufactured, it is cut into the required lengths and assembled with fittings or connectors at both ends. These fittings are designed to securely attach the pipe to the fuel tank and the engine’s intake system.

The primary function of a petrol pipe in a two-wheeler is to transport gasoline from the fuel tank to the engine.

One end of the petrol pipe is connected to the fuel tank. This connection is usually located at the bottom of the tank, where gasoline is stored. The other end of the petrol pipe is connected to the engine’s fuel intake system. This connection allows gasoline to be delivered to the engine, where it can be mixed with air and ignited to power the vehicle. In some two-wheelers, especially those with fuel injection systems, a fuel pump may be integrated into the petrol pipe or the fuel tank. The pump pressurizes the fuel, helping to ensure a consistent flow to the engine. The flexibility of the petrol pipe allows it to accommodate the movement of the two-wheeler, such as when the handlebars are turned or the suspension is compressed. This flexibility ensures a continuous flow of fuel even when the vehicle is in motion. Petrol pipes are designed to be leak-resistant and durable. They undergo rigorous quality control tests to ensure they can withstand the corrosive effects of gasoline and maintain their integrity over time.

Petrol Pipes

1. Do we manufacture these Petrol Pipes ourselves?

– Yes! We are a manufacturing company and we manufacture almost every product you will find on our catalogue.

2. Do We Deal in only bulk Quantity or Small quantities?

– Yes, We only deal in bulk quantities with Wholesalers, Traders, Distributors, Retailers.

3. How is the Quality of your Petrol Pipes? Is it heavy quality or you manufacture more than one quality?

– We manufacture two types of qualities. One is the heavier quality which can be sold with brand names, and the other quality is of slightly lighter quality. It’s up to your needs to go for your required quality.

4. What about the packaging?

– We have three types of packaging available one is plain packing which comes with plain polythene with stickers, second is

Contact Our Team To Get Information According to your Requirements or Book a Visit to Our Manufacturing Units!